Due to the experience of almost 30 years in the field of concrete block production and plant design, we have a wide range of possible solutions to bring the customer decisively forward. A large number of completed orders in the national and international environment give us this planning security.

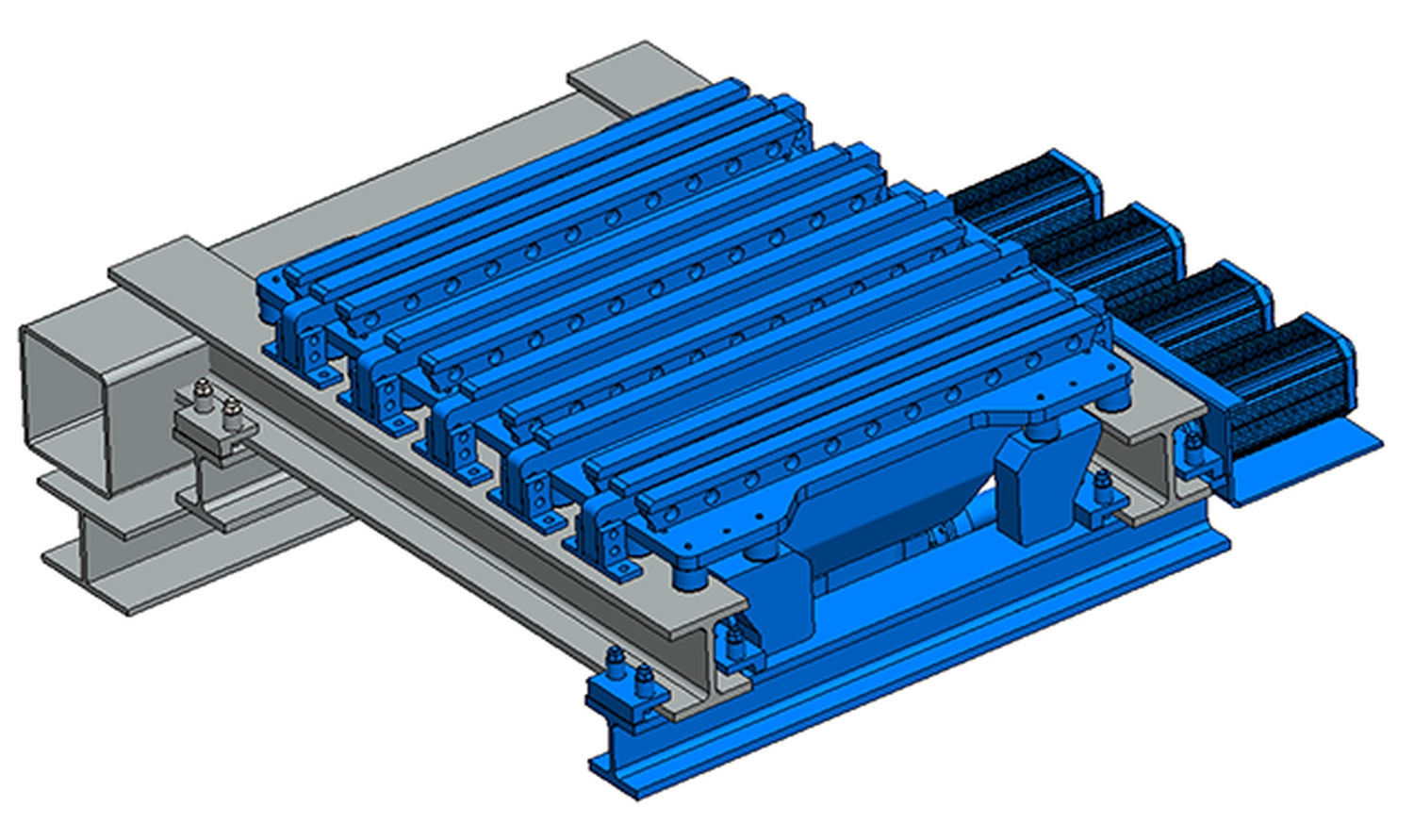

If the foundation and installation environment have the necessary trustworthy basic substance, we will create a corresponding customer-specific conversion concept for you. Strategies for installing single and double tables can be implemented. It is also possible to convert to modern long-life vibration systems if the structural requirements are right.

We equip existing machines with our tested and proven long-life vibration system in order to achieve significant increases in system availability and compaction capability for you.

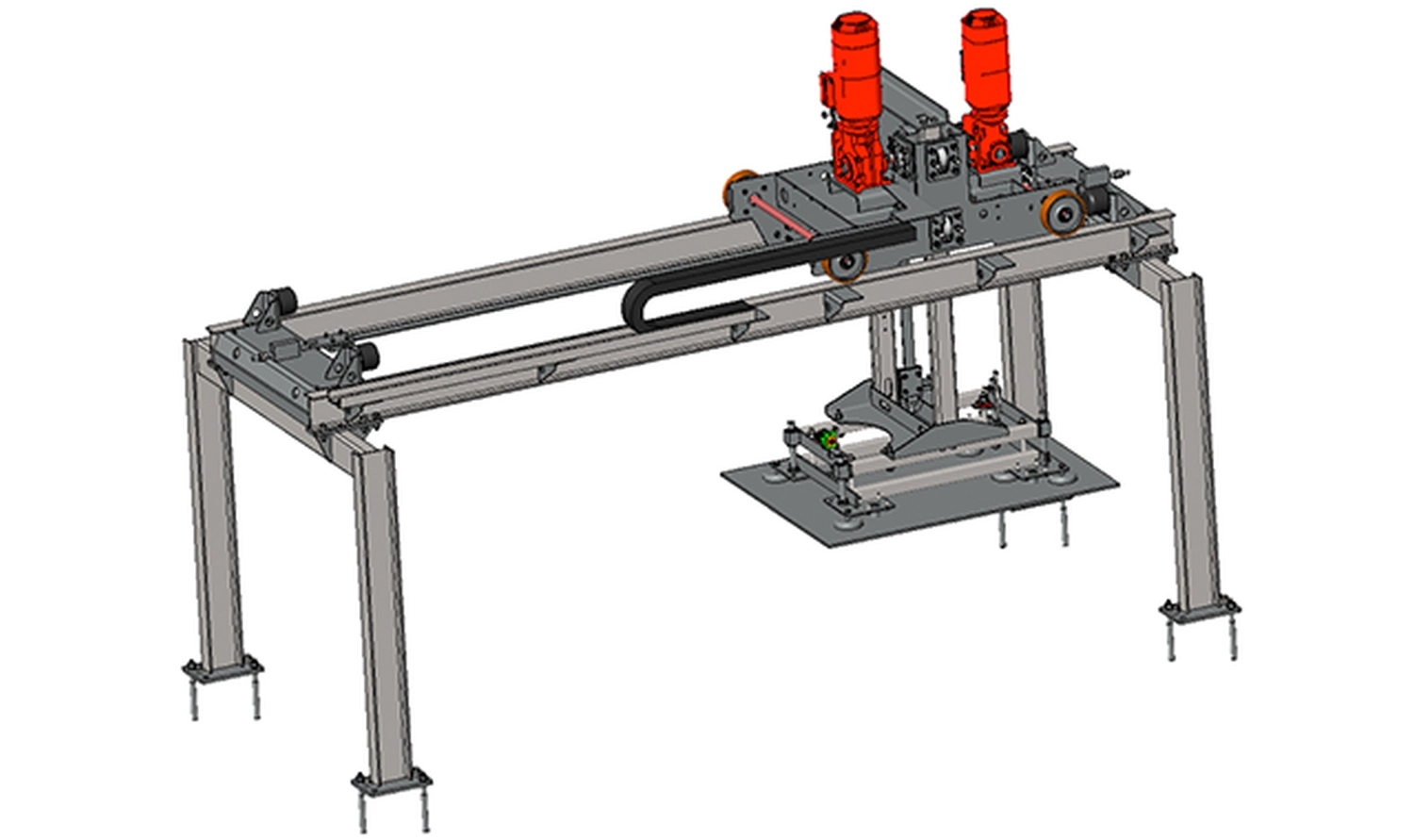

We develop complete concepts for the construction / production of block making machines of all known board sizes. Our product range extends from the simple standard machine with a simple design to the high-end machine for constant 3-shift operation.

In our work, we take into account the market-oriented machine design (machine size, performance), the cost-effective procurement of purchased parts, as well as the efficient product structuring and production of the machine components.

The 3D CAD construction phase, as well as the production phase, are securely monitored and accompanied by us in order to be able to achieve a very high production quality with the first machines built.

The machines can be equipped with all commercially available vibration systems, up to the high-end – 4 servo vibration motors – with SEW drive technology

Heavy wear and tear from dust/dirt and almost permanent 2 to 3-shift operation takes a corresponding toll on the hydraulic unit of the block making machines in terms of service life.

We have designed and built a correspondingly powerful performance unit, which has a modular structure and can be easily installed as a replacement unit in existing systems. It consists of two separate system parts, the vertical valve stand and the freely positionable tank/pump unit.

The following aggregate variants exist:

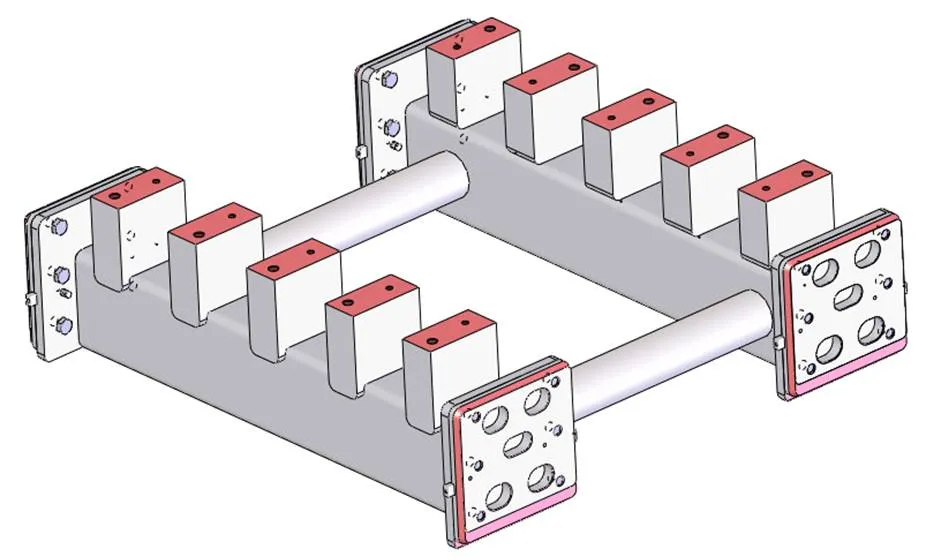

The optimal function of the mold clamping has a decisive influence on the vibrating ability of the mold and the correspondingly even filling of the mold. With our adapted variants, we can offer appropriate solutions that allow flexible adjustment to a wide variety of production conditions and molding systems. Talk to us about detailed information about this system.

We create your filling car according to your individual wishes, or provide a concept based on our experience. Tell us your special needs - we will implement them, suitable for any existing block making machine!

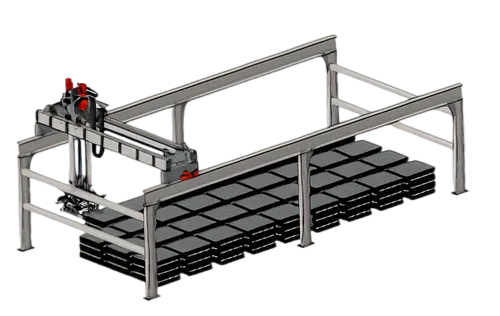

The design concept of our E-Cuber is based on the use of exclusively electric motor drives - for a powerful and dynamic movement of the mast, trolley and slewing gear. The gripper clamp is driven electro-pneumatically, for fast movements by the electric motors, and a precise adjustable clamping force application for the product to be packaged (thin wall thicknesses, green state of the product). This drive concept enables the cuber to be freely programmed in any way, and protects the customer's products from contamination from hydraulic oil in the event of creeping leaks on the lifting device or clamp. Cycle times of less than 10 s per individual layer are possible with the appropriate SEW drive technology. In terms of control technology, a wide range of customer needs can be implemented, including additional tasks to be carried out with the cuber. The entire structure of the mechanical components is characterized by a robust design that is consistently designed for 3-shift operation. The standard payload of the Servo E-Cuber is 600 kg, other payloads on request.

In order to be able to run products up to 500 mm with the plant, only every second board is used during production. This means that almost half of the boards in the plant have to be temporarily stored in a buffer. Depending on the space available in the system, the board buffer must be specified and designed accordingly. The illustration shows a possible variant - for steel production boards.

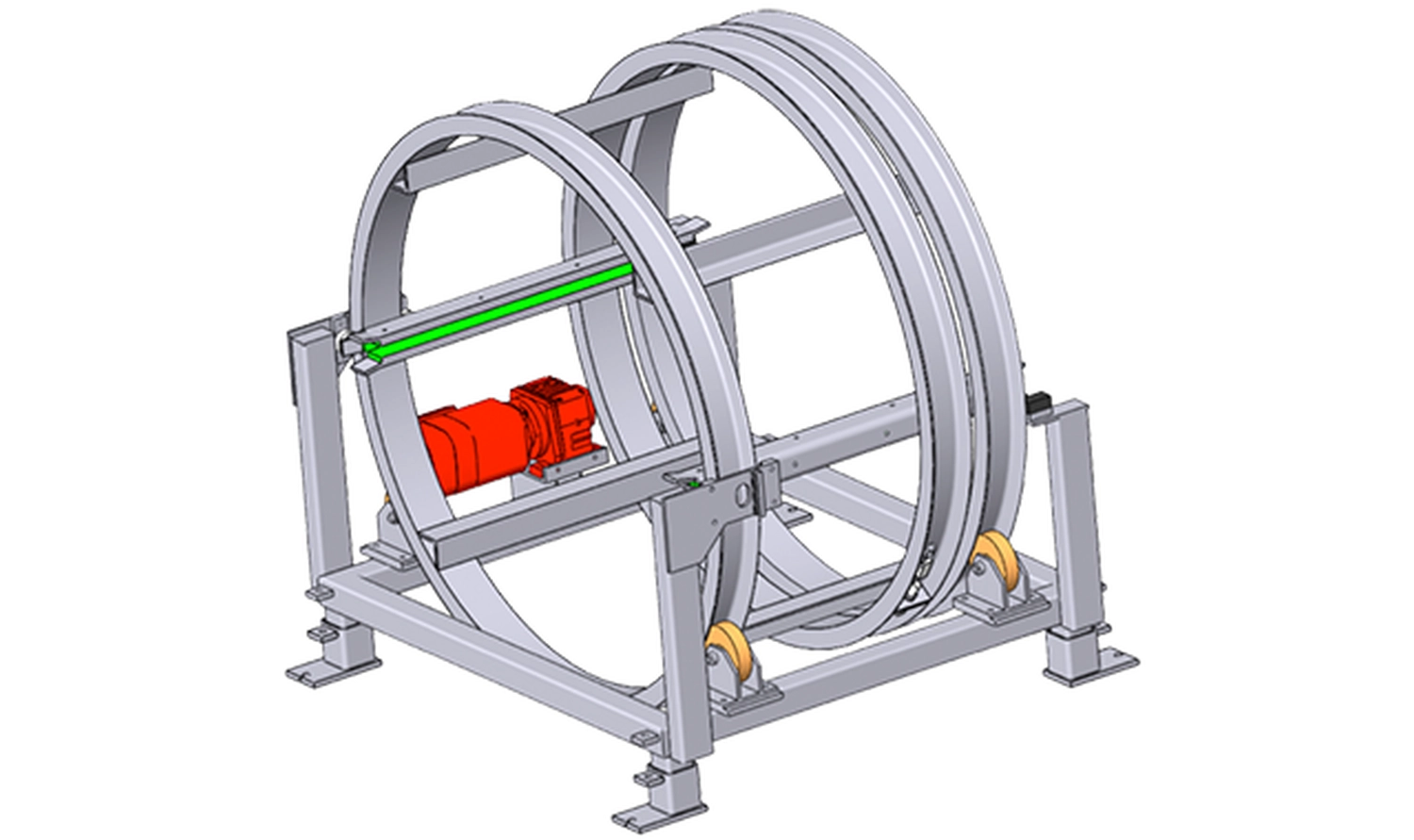

If the board cannot be rotated within 2 positions due to a lack of space in the plant layout, the principle of the drum turner can be used in the plant.

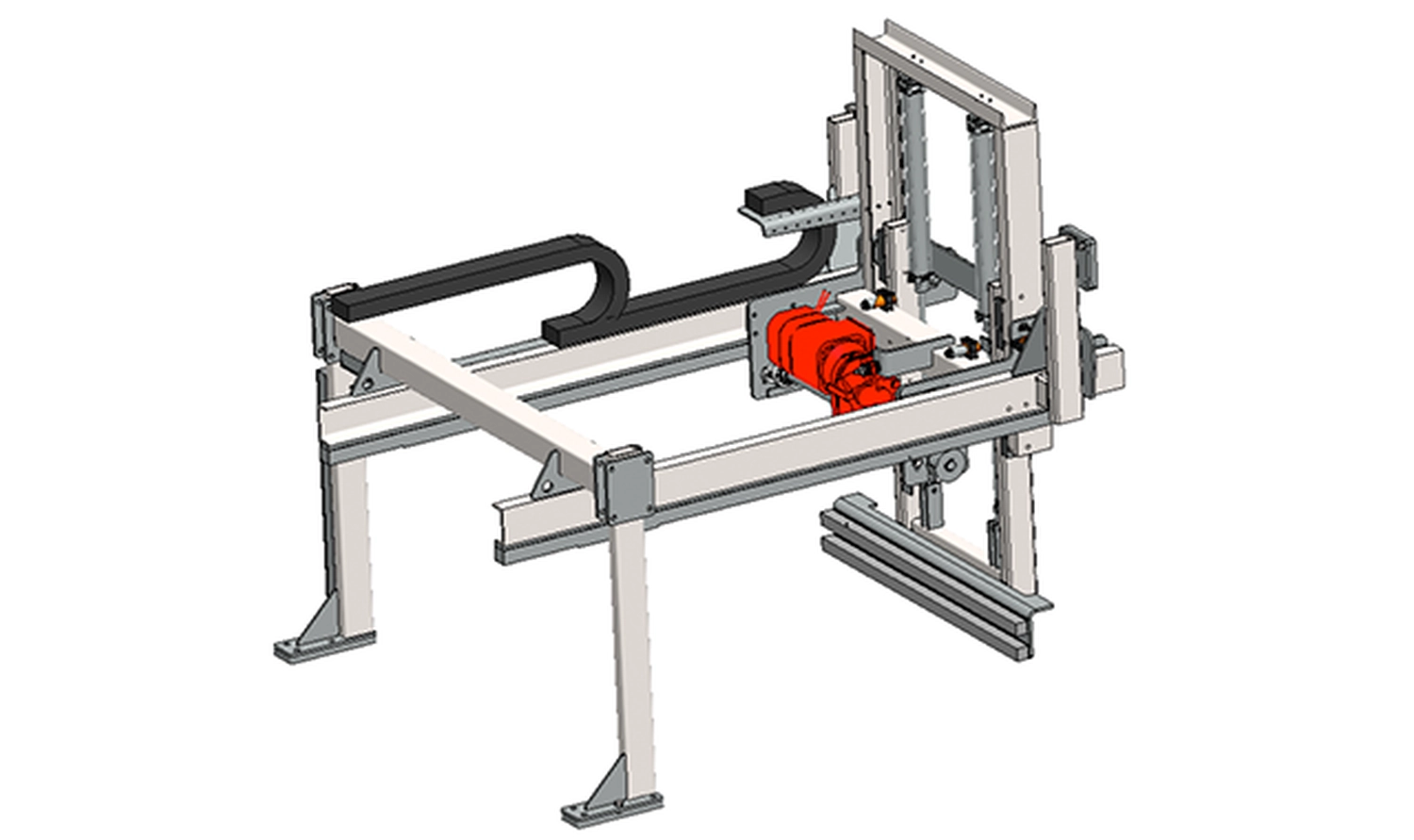

The stone layer pusher can be used to feed the individual stone layers to various post-processing stations. The device is equipped with a lift and slide function, with which up to. 400 kg heavy stone layers can be pushed.

Stacker / Destacker adder can be created in any possible conception. Up to 20 / 22 levels / single stroke board / double stroke boards. Important functions such as durable chains, chain guides and chain positioning are part of our standard concept. Reliable and well synchronized drives are a must.

The board stacking device is used to form and destack the board packages. The design shown here enables careful destacking of boards without board wear. The device can also be used for easy board transfer from point to point, with slewing gear, turning grab. Short cycle times can easily be achieved with these devices.